Some of Our

Recent Projects

Compressor Upgrade – Diffuser Repairs – Exhaust Plenum Refurbishment

Compressor Upgrade – Diffuser Repairs

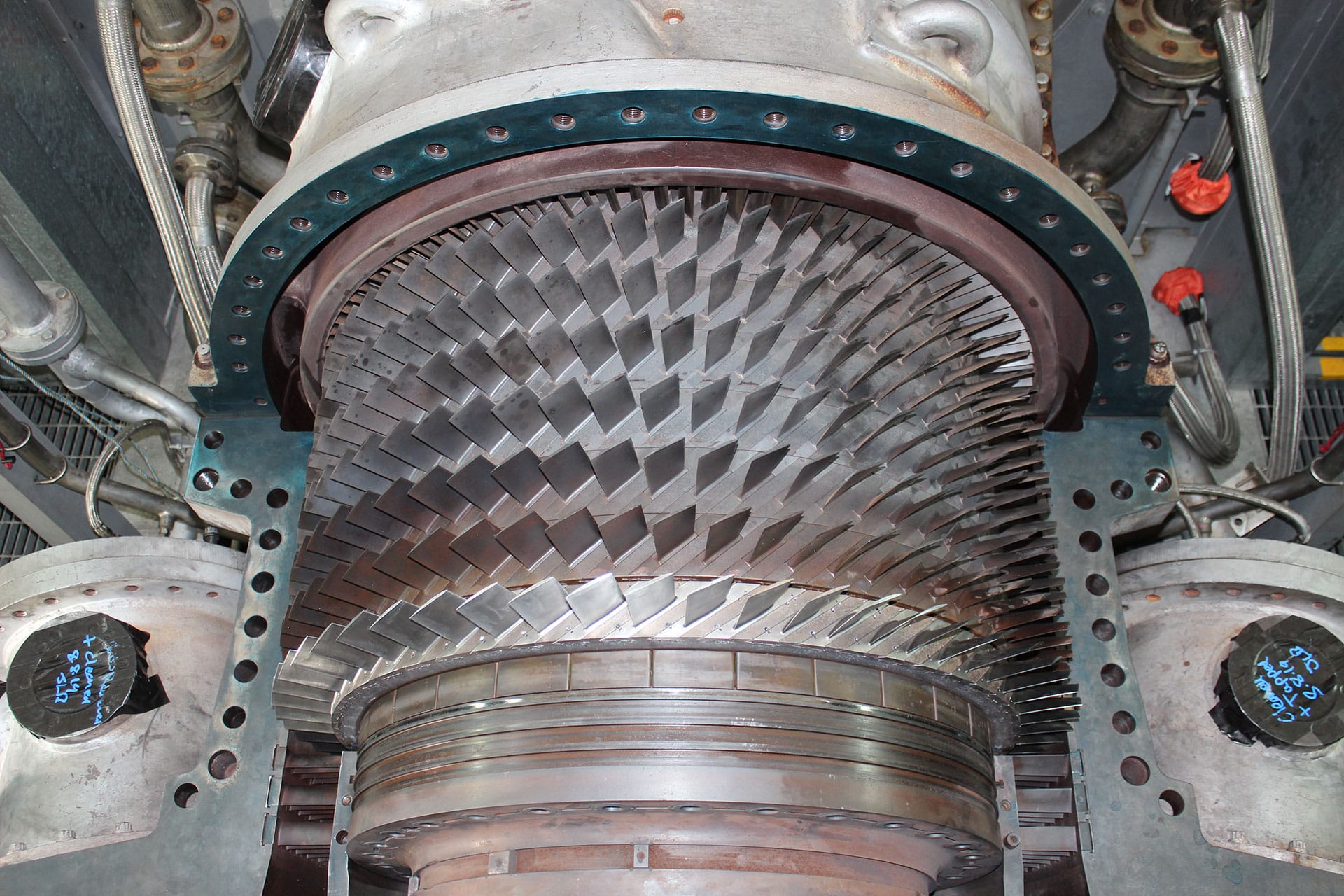

ATMSGroup has completed HGP and MI inspections on AGL energy’s Somerton peaking units working with the client we highlighted several areas which required attention, these included 1st and 2nd stage turbine blading replacement and due to progressive shim migration the in-situ reblading of the 16th Stage Compressor Stationary and 17th Stage Compressor Rotating blades. This was a first for these units in Australia. During the outage we found other potential issues that could impact the reliability and performance of the turbine, these were communicated quickly and outcomes to facilitate the repair of these were developed with the client so as not to impact the critical outage timeline.

ATMSGroup is proud of our relationship with AGL that has spanned 6 years and we are excited continue to provide services and support them well into the future.

EnergyAustralia Hallet

GE Frame 5

Major Inspections and HGPI

2nd Stage Turbine Buckets Upgrade

With 12 GE frame 5 turbines of varying ages ATMSGroup and EnergyAustralia through a long-term partnership have been able to develop a maintenance and outage cycle to service these units. ATMSGroup continues to grow with EA and provides minor inspections through to major overhauls.

Transgrid Broken Hill GE Frame 5P Major, HGPI & Generator Inspections

Newcrest Mining Lihir Gold Mine

GE Steam Turbines

Major Inspections and Repairs

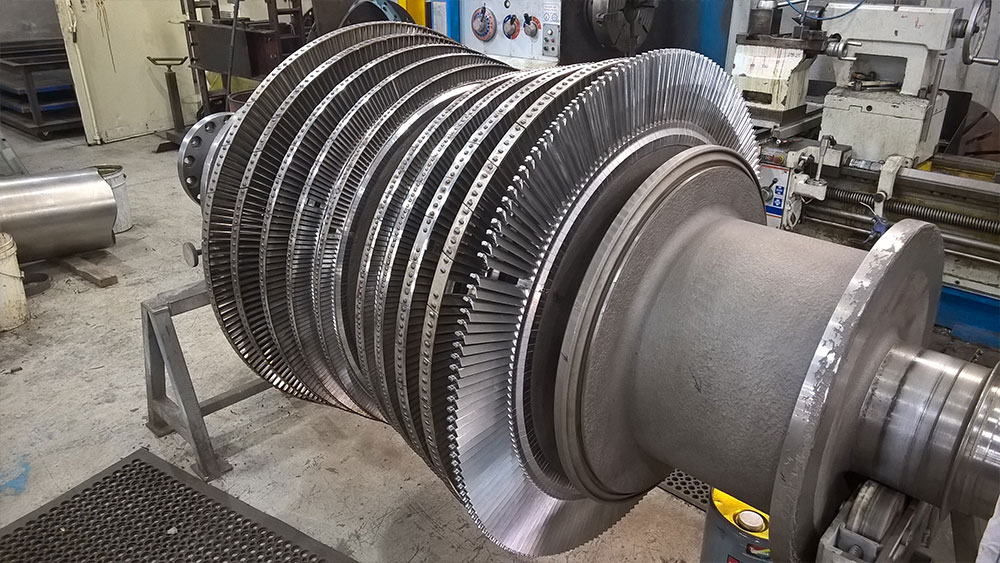

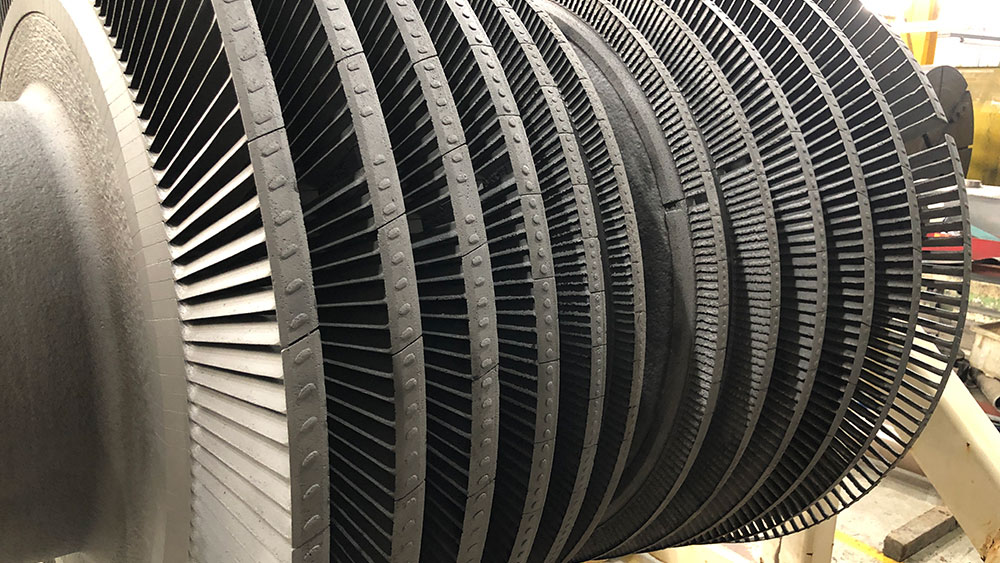

CNC Turbine Blading Manufacture

Newcrest engaged ATMSGroup to project manage major repairs of their 20Mw GE steam turbines located at Lihir gold mine in Papua New Guinea, this included the relocation of the turbine rotor and casing to Australia, de-blading of the rotor discs and manufacture of a complete set of turbine blades to suit the application.

Port Lincoln Power Station

ATMSGroup has provided inspections and repair solutions to South Australia peaking units for a number years, ranging from Borescope Inspections to Asset Relocation from overseas to Australia. This was delivered on time and on budget.