Our Complete

Range of Services

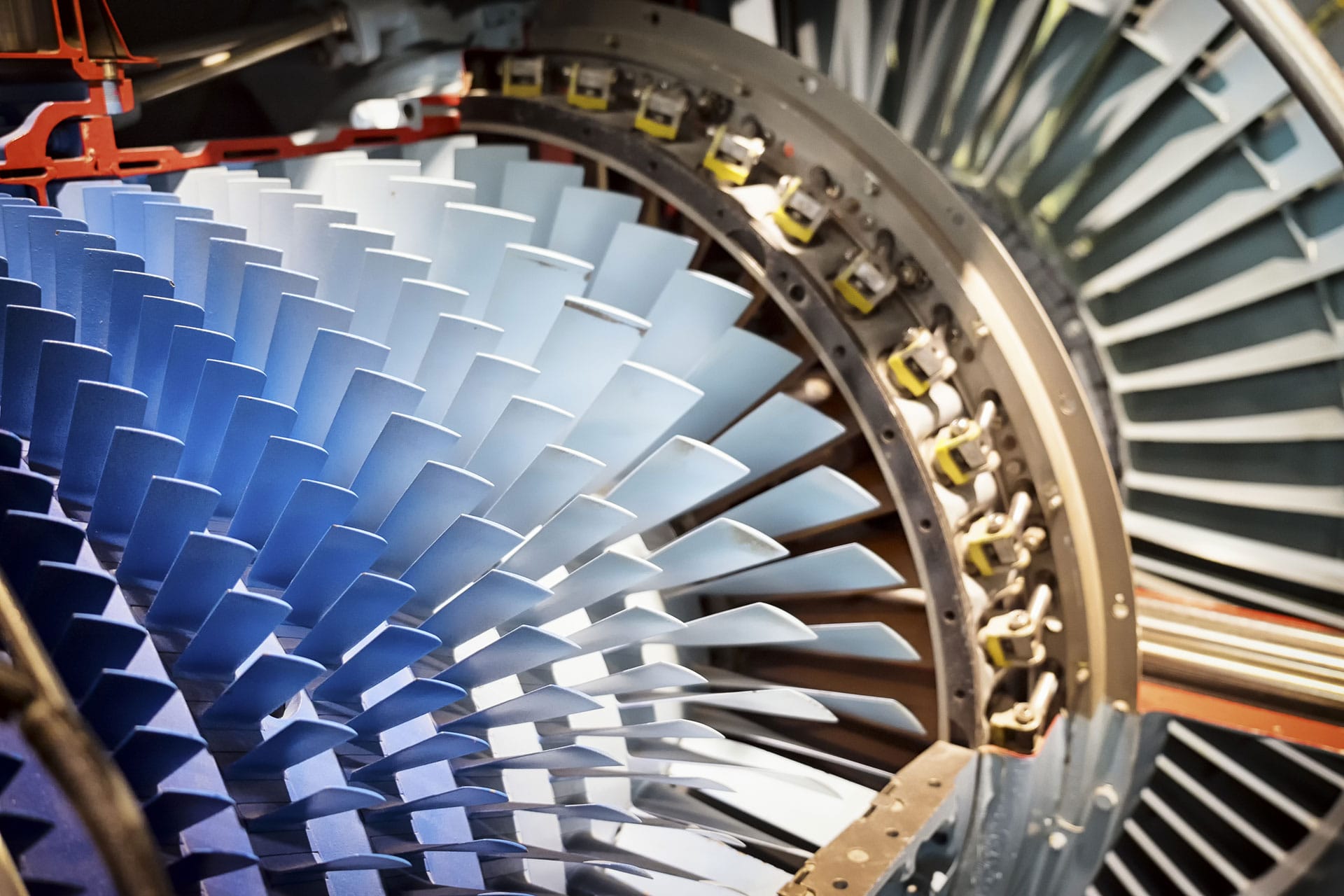

ATMSGROUP holds expertise in providing maintenance support for owners and operators of gas / steam turbines and rotating equipment that are used in the energy industry worldwide. Our excellent practical operations and maintenance experience are the factors behind ensuring, market leading services for Power, Oil & Gas and Petrochemical applications. We focus on delivering cost-effective performance throughout the life cycle of our client’s assets is also instrumental in making us one of the preferred choices across the globe.

Whether it’s an inspection, major overhaul or relocation of assets ATMSGROUP provides the solutions to get the job done.

What We Offer

Our goal is to help our customers extend the life of their equipment and enhance the productivity of their operations by providing the following:

Mechanical Fitting

Our specialised mechanical technicians are some of the best in the industry having worked with rotating equipment for over 10 years. We can provide not only rotating equipment services but specialised mechanical labour to execute all scopes of work during shutdowns, turnarounds or during your day to day operations

Electrical & Instrumentation

ATMSGROUP have the know-how and the latest equipment to provide detailed electrical and instrumentation solutions to meet your field requirements whether it be annual calibrations servicing & audit reporting of hazardous area electrical and instrumentation components or installation of new components we are poised to deliver and can help to develop routine inspection schedules to ensure your equipment meets the stringent industry requirements

Borescope / NDT inspections

ATMSGROUP are proud to be using the latest in GE borescope technologies to provide an industry best fault and life expectancy reporting. Our in-depth knowledge and support will help you in making the best possible decisions when it comes to your equipment which means more time operating and less time offline.

Specialised Repairs

With a dedicated welding and machinist team we can provide difficult and challenging in situ weld repairs to your equipment where replacement isn’t possible. Our machining team is able to provide complex solutions with access to the latest in CNC technologies we can manufacture hard to access components and provide repairs that others simply can’t.